How Does Traffic Light and Vehicle Loop Detector Installation Work?

The Los Angeles Signal Construction firm offers traffic light detectors, which are devices installed at traffic signals to regulate the flow of automobiles. Los Angeles Signal Construction understands the necessity for traffic control and its relevance in these times of increased traffic. The business has created a wide range of detectors to optimize traffic signal control. These can identify people, bicycles, and automobiles across a large distance on one or even more lanes. This addresses the road congestion on busy highways and allows traffic to flow freely and without interruptions.

Why do we need to install traffic lights sensors?

Having installed one or perhaps more traffic light detectors can help decrease vehicle buildup. This avoids unnecessary traffic congestion. It will also improve traffic flow and thus reduce CO2 gases into the environment.

When installed at a traffic signal or interconnection, the sensor detects vehicles in a number of predefined regions. So, it stimulates one or more relays. The green or red light will then be activated by these transmissions. A radar antenna is attached to the traffic light sensor to detect vehicle movement. This antenna sends out frequencies reflected by the vehicles.

How to Detect Vehicles?

There are several methods for detecting vehicles, varying from fittings style identification to ultra – sonic sensing to an inferential loop. Inductive (magnetic) circuit technique is by far the most reliable for traffic enforcement or drive thru.

1. Inductive Loop Vehicle Detector:

An impedance loop vehicular sensor system is made up of three parts:

(1) a formulated or sawcut loop

(2) extension loop cord and

(3) an electronic detector

While having installed or fixing an inferential loop, even the slightest thing can make the difference among dependable and sporadic detection and tracking. As a result, paying strong attention to detail once trying to install or diagnostics an inductive loop vehicular detection method is crucial.

2. Saw-cut Loop Vehicle Detector:

The sawcut or preformed loop is tucked away in the driving lane. The circuit is a prolonged wire run that enters and leaves at a single point. The loop wire’s two parts are linked to the circuit extension lead, which is then connected to the vehicular sensor. The sensor controls the loop, creating a magnetic flux in its vicinity. This same circuit rings true at a given frequency, which is monitored by the detector. Whenever there is no vehicle on the loop, a base recurrence is formed.

The resonant frequency expected outcomes when a big metal artefact, such as a motor, shifts over the loop. The latter boost in intensity is detected and, depending on the detector’s design, causes a usually open transceiver to close.

This same circuit would then stay sealed till the vehicle exits the circuit and the rate goes back to zero. This same signal can activate a variety of devices such as a multimedia intercom, an entrance, a traffic signals, and so on. A small car, in particular, will result in a greater frequency boost than an entire vehicle or truck.

This happens because of different metals here on vehicles under carriage are connected to the circuit. When especially in comparison to an utility vehicle, the under carrier of a race car is nearer to the magnetosphere of the circuit. A smaller car does have a higher – frequency alteration.

Detection of the Vehicle:

It is widely assumed that inferential circuit detection method is based on metal mass. This is not correct. The detection is based on the metal surface area, also known as the skin effect. The greater the metal surface area in the same plane as the loop, the bigger the frequency increase. One square foot of sheet metal, for example, placed in the same plane as the loop, has the same effect as a metal piece one foot square one and foot thick. Another example is to take the same one square foot piece of sheet metal that is easily detected when held in the same plane as the loop and turn it perpendicular to the loop. It is no longer detectable.

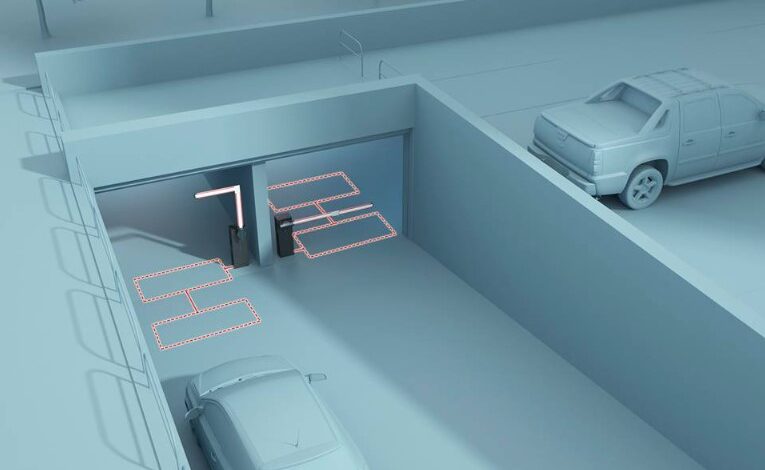

Installation of the Loop

- To lay the loop into the ground covering, first cut a slot into the concrete or asphalt with a diamond disc.

- Each slot should be approximately (40-70) mm deep and (5-8) mm wide.

- Dampness must be avoided while cleaning.

- The loop wire can then be installed. A standard flexible and isolated copper line HO7V-K1.5 (NYAF1.5 mm2) can be used as the loop wire.

- A diagonal joint with a 45° angle must be cut at the edges of doors, gates, and barriers, through which the loop wire is led.

- This avoids putting far to much stress on the circuit cable’s corners. The rounding off of sharp joint corners by digging is recommended in the area of highways.

- Due to the stress imposed by passing vehicles, there is a risk of breaking edges. As a result, it is preferable to bore in this zone.

Installation of the Induction Loops:

Attention should be paid to the following points when laying induction loops:

- The loop inductivity should be measured by means of an L-Meter or a loop diagnostic device.

- The floor shading has to be steady and free of cracks.

- A horizontal joint should be reduced just at joint corners or grooved at the joint corners.

- When inserting the circuit cables into the vacant spot, pay close attention to the edges.

- The circuit cable must be free of any insulating materials damage.

- The circuit wire really should not protrude from any portion of the connector, or else the isolation will be devastated or the cord will start ripping apart. To avoid washing up during the casting, it is best to secure the loop cord with timber slices.

- Before casting, the loop port has to be smooth, dust-free, and cleaned. Just after concrete, the circuit cables should not move.

Much of the time, absorption is insufficient to indicate a certain perpetual availability. As a result, if feasible, the circuit must be laid at a 45° angle to the designated points. It will result in increased responsiveness. If there are iron formation beneath the loop, identification of two-wheeled cars and trucks is therefore no longer offered. At about this phase, various tests with the circuit specific diagnostic set SDG3000 must be performed. If you are looking for Vehicle Loop Detector Installation services the you can rely on The Los Angeles Signal Construction company Inc.