How To Run a Hydraulic Press?

Every man has his hobby and one of the most fascinating hobbies may be the hydraulic press. Although you can find tons of videos on YouTube, I wanted to share my unique experience with a hydraulic press.

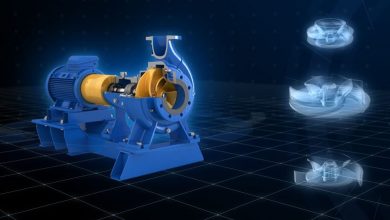

Testing the press

The first step is to find out the best hydraulic press for sale at Asset Plant & Machinery, second is to build your own hydraulic press and test it. The first press I built was based on plans from the internet, but none of those plans showed me how to test the press once it was made. This left me with a big problem. I could not be sure if my press was working correctly or if it would break under pressure.

Once I figured out how to test my press, I was able to use it without any problems every time. It’s easy to test your own hydraulic press as long as you have access to a hydraulic pump or at least a bicycle pump. You don’t need much money for this project because all you really need is an air compressor and some 1/2″ pipe fittings.

Treat the press with care

The main thing that you need to remember when using a press is that it must be treated with care. When you are choosing a part of the machine to press, always ensure that you choose parts that are suitable for pressing. Avoid pressing objects that have sharp edges or may damage the press like glass as it might break and cause injuries. Also, remember to wear protective equipment like goggles and gloves to avoid injuries and damage to the eyes and skin while working with a hydraulic press. Use the right amount of pressure when pressing objects. The pressure applied will depend on what you want to achieve as well as the material being pressed. For example, if you want to make an impression on the surface of an object, then less pressure will be required than when making a hole in the object. It is advisable to set up your machine for different pressures for different items so that you can adjust easily according to your need. Ensure that there is no oil leakage from the pump when operating it.

Treating the hydraulic press like a weight bench

Set the pressure to around 80 percent of the maximum capacity, which will give you plenty of room to raise and lower it safely. Place the object that you want to crush under the piston, then slowly lower it until it starts to make contact with your item. Slowly increase the pressure while simultaneously lowering the object until your item is completely crushed. Then open the valve and let all the pressure release at once, which will propel your now-crushed item up out of its grave.

Common sense prevails

When running the hydraulic press, it is important to use common sense. Most importantly, never place your hands or fingers inside of the press while it is running. Always place your hands outside of the press while operating it and make sure that there are no obstructions in the way of the ram while it is moving up and down. Make sure to keep a safe distance away from the ram as well. It is also important not to force the ram down as it can cause serious injuries if misused.

Also, make sure that you are using proper safety equipment when operating a hydraulic press. Safety goggles should be worn to avoid any possible injury from flying debris. A hard hat should be worn if there is any chance of falling debris or items being ejected from the press. Earplugs are also a good idea because they will help to protect your ears from any loud noises caused by the press itself.