Choosing the Right Grinding Wheel

A grinding wheel is use for precise cutting of delicate and sophisticated objects. It has abrasive grains on its surface, held in place by a bond matrix, which act as cutting points. The abrasive grains are separated by pores, i-e hollow spaces between them and the bond. Pores allow a grinding wheel to clear up the discarded chips during grinding process. This way the process of grinding remains mess free and precise cutting is ensured. Grinding offers a Water Free Dicing Service for cutting sophisticated objects.

During the process of grinding, the abrasive grains become blunt due to wear and tear caused by friction. This results in fracturing the abrasive grain, or damaging the bond bridges, which leads to exposing new cutting edges.

Abrasive Used for grinding wheels

There are 4 types of abrasive grains available for grinding wheels.

1. Ceramic Aluminium Oxide

Ceramic Aluminium oxide, also known as ceramic, is harder and sharper than other abrasive grains. Having a microcrystalline structure, ceramic is self-sharpening, which reduces the need of maintenance of dressing. It also ensures cooler and Water Free Dicing Services.

2. Silicon Carbide

Silicon carbide is a versatile abrasive material, which is even harder than ceramic aluminium oxide. It is ideal for grinding a wide variety of metals- whether hard metals or soft metals. It is ideal for grinding aluminum, cast iron, and even harder materials like cemented carbide.

3. Zirconia Alumina

This abrasive material is ideal for use in grinding rough applications, where high stock removal is required. This grain is associated with high tech resin bonds used for Grinding & Dicing Services and also for Water Free Dicing Services.

4. Aluminium Oxide

Aluminum oxide is used for grinding high tensile strength materials. They include stainless steel and tool steels. They are ideal for using on high tensile aluminum and bronze alloys. There are various qualities of aluminium oxide, which are used for grinding as per the requirement of cutting subject.

Picking the Grit Size

Coarse size:

If the project does not require finesse and neatness in cutting, a coarse grit can be used. A coarse grit is ideal if you want to speed up the grinding process, or if the area under operation is big. Coarse grit works great for soft, ductile and stringy metals such as stainless steel and aluminium.

Fine Grit

Fine grits is used when the precision or accuracy cannot be compromised. Fine grit is ideal for grinding and dicing services when neat finish is integral to the success of the project. Other than this, when the operation area is small, picking fine grit is appropriate. It is preferred for grinding hard and brittle materials such as cemented carbide, glass, and tool steel.

Picking grinding wheel grade

The holding power of the bond, which holds the abrasive grains in their place, is indicated through its grade.

Soft Grades:

Soft grade grinding wheels are chosen for Grinding & Dicing Services of hard materials, such as hard tool steels & carbides. They are recommended for operating a large area of contact or when you need rapid dicing services.

Hard Grades:

As opposed to soft grades, hard grades are chosen for operating soft materials. When the operated area is small or narrow, picking a hard grade is more suitable. It helps grinding wheel have a longer life.

Before picking a grinding wheel, you must consider these factors and then decide which type to pick:

- The material you are going to grind or dice, and its hardness.

- Separating material i-e the stock which needs to be removed

- Keep in view the shape of the material and the surface finish

- The type of machine you will use

- Speeds and feeds to be used

- Size and hardness of operated area

- Dry or wet grinding operation

- Requirement for grinding severity

- Dressing method

Final Words:

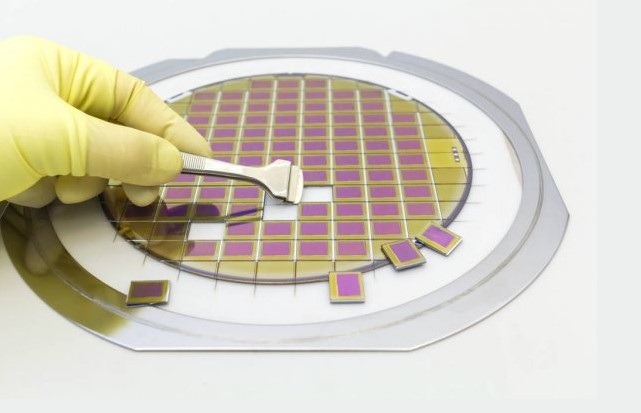

For premium quality Water Free Dicing Services and Grinding & Dicing Services Company talk to our Wafer Dicing Service Provider representative today. You can discuss the delicacy of your project and figure out the kind of grinding services you need. At GDSI, , our team is experienced in carrying out Grinding & Dicing Services, and Water Free Dicing Services.