An Overview of Centrifugal Pumps

Centrifugal pumps are dynamic-displacement machines that can handle low-viscosity fluids at low-to-moderate pressures in high-volume applications. They are the pump of choice in many industrial applications where water and other fluids of similar viscosities have to be moved, often in enormous quantities, due to their simple design and minimal moving parts.

The pumps, according to their name, use centrifugal force to perform their functions and include all rot dynamic pumps in their fold.

Positive displacement pumps and kinetic pumps are the two types of pumps, with centrifugal pumps falling into the latter category. Horizontal Centrifugal Pump come in a variety of sizes, forms, and types, ranging from large to small, high pressure to low pressure, and are used to transfer liquids to gases, among other applications.

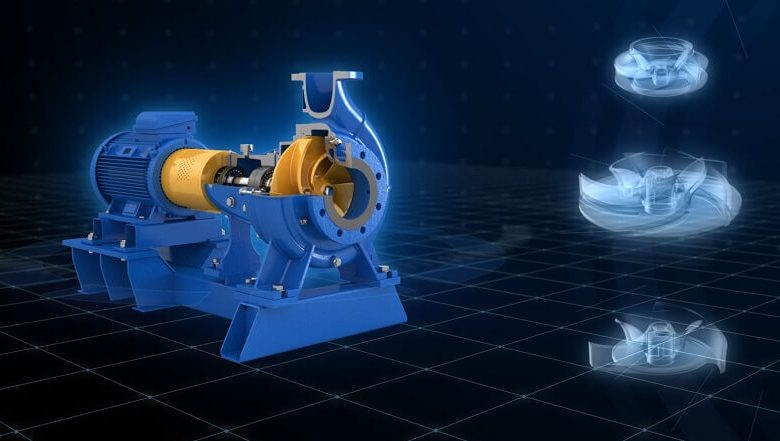

A centrifugal pump’s basic construction is made up of six segments, which are as follows

- Impeller

- Pump body

- Bearing

- Pump Axis

- Seal Ring

- Stuffing Box

Now, let’s discuss them one by one

Impeller: The impeller is the most crucial part of the pump, and it is responsible for supplying a lot of power because of its fast rotational speed.

Pump Body: The pump body, often known as the shell, is responsible for supporting the entire apparatus. The pump axis transmits the torque from the electric motor to the impeller.

Bearing: while the bearing sustains it.

Seal Ring: The seal ring plays a vital function in the centrifugal pump’s operation; it helps to regulate internal leakage, extend the time of operation, and boost reflux resistance. The seal ring is placed at the point where the impeller’s outer edge meets the inner edge of the shell.

Stuffing Box: The stuffing box is made up of stuffing material, a seal cage, and a water sealing pipe, among other things, and its main role is to close the gap between the axis and the shell.

Purchase Considerations

The importance of choosing a decent pump cannot be overstated, and there are various variables to consider. The application’s pressure and volume requirements, as well as the material to be pumped, are the most important factors to consider. It might be anything from water to fertilizer to oil to any other substance that needs to be pumped. Another factor to consider is the horsepower needs in terms of discharge pressure and volume. In these cases, centrifugal pumps are an ideal alternative because they require less maintenance and can effectively handle suspension.

The back pull-out pump is one of the best designs of a centrifugal pump, according to back pull-out pump dealers, since it has an added advantage. The rear end of a rear pull-out pump, including seals, drivers, couplings, and the shaft end, can be withdrawn or dismantled for inspection, maintenance, service, and overhaul without disrupting the pipework.

The ideal individuals to contact for finding the proper centrifugal pump for your application are back pull-out pump dealers. To receive top-quality products for your application, check out the reliability of all mechanical item dealers, such as back pull-out pump dealers, inline helical dealers, and helical gear dealers.

When compared to other pumps, these pumps are less difficult to install. They’re made using a back pullout-design technique. In the event of a repair, the pieces can be dismantled, repaired, and work resumed in a short time. However, to achieve the finest results, you’ll need the help of a specialist.

Industrial Uses

Centrifugal pumps are used in a variety of industries, including environmental facilities, textile mills, power plants, food processing plants, and water desalination plants. Centrifugal pumps are also ideal for usage in large gardens and aquatic ponds.

Malfunctions

If you have an inexperienced operator, the electric motor will automatically suffer since the impeller will suffer. In this circumstance, quick action is required. The impeller has become corroded if the centrifugal pumps show signs of vibration and make noise. Corrosion may have occurred as a result of some of the particles entering the impeller. For proper functioning of the centrifugal pump, the impeller must be replaced.

If the pump has low pressure or a low level of chemical fluids, the pump must be heated to ensure that the flow is smooth. Unbalance can occur if the shaft and impeller are not properly aligned. The pump may shake violently, causing other parts to loosen and the entire system to be damaged.

Summary

This article provided a brief overview of various components, purchase considerations, and centrifugal pump malfunctions. Please visit https://www.pricepump.com/ for more information and other related products.